The Process to produce Borneo's Bounty Super Fine Kratom

Kratom, scientifically known as Mitragyna speciosa, is a tropical tree indigenous to Southeast Asia, renowned for its leaves. The cultivation, harvesting, and processing of kratom involve a careful and precise series of steps to ensure the production of high-quality leaves. Here's an overview of the process:

1. Kratom Cultivation:

The process begins with the cultivation of kratom trees. These trees thrive in a tropical climate with well-drained soil and ample sunlight. Kratom is usually propagated from seeds or cuttings. Farmers plant the young saplings in nutrient-rich soil and provide regular irrigation and care as they mature.

2. Tree Maturation:

Kratom trees require several years to reach full maturity, typically around 2 to 5 years. During this period, the trees develop lush foliage containing the valuable alkaloids. The leaves' potency and alkaloid content vary depending on factors such as the tree's age, soil quality, climate, and harvesting methods.

3. Harvesting:

Once the trees have matured and developed healthy leaves, the harvesting process begins. Skilled harvesters carefully select leaves for harvesting based on their appearance and alkaloid content. The harvesting process involves carefully plucking individual leaves from the branches while leaving behind a portion of the foliage to ensure the tree's health and regrowth.

4. Removing Stems and Veins:

After harvesting, the leaves are sorted and the stems and veins are removed. Stems and veins contain fewer alkaloids and are typically discarded. This step is crucial to enhance the overall quality and potency of the final product.

5. Sorting by Color Vein:

Kratom leaves come in a variety of vein colors, including red, green, and white. These colors are indicative of the alkaloid composition and potential effects of the leaves. The leaves are sorted based on their vein color to create distinct kratom strains with unique properties.

6. Drying:

After sorting, the leaves are carefully spread out and air-dryed indoors. Drying is a critical step that helps preserve the alkaloid content and prevent mold growth.

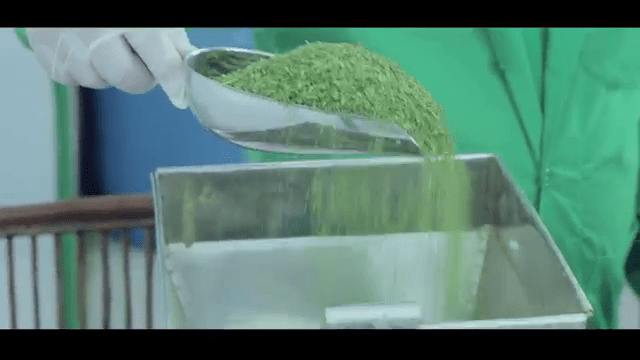

7. Grinding and Processing:

Once the leaves are thoroughly dried, they are ground into a fine powder. The grinding process converts the leaves into a consistent texture that is easy to consume. The resulting kratom powder is then packaged and stored in airtight containers to maintain its freshness and potency.

8. Quality Control and Packaging:

Before packaging, the kratom powder undergoes stringent quality control checks to ensure that it meets the desired standards in terms of color, aroma, texture, and alkaloid content. Once approved, the powder is carefully packaged, labeled, and sealed to prevent contamination and maintain its shelf life.